The Problem

My garage door opener started exhibiting symptoms that pointed to a classic torque limit issue. The door would struggle to open, sometimes stopping mid-cycle, and the motor would sound strained. The typical signs were all there:

- Door would start opening but stop before fully retracting

- The opener would reverse direction as if it hit an obstruction

- Got worse rapidly, would only work if I helped it.

Initial Diagnosis: Torque Limit

When a garage door opener behaves this way, the most common diagnosis is that it’s hitting its torque limit. This can happen due to:

- Misaligned tracks

- Worn or damaged rollers

- Binding in the door mechanism

- Excessive friction in the system

- Obstructions in the track

I checked all of these common culprits:

- ✅ Tracks appeared properly aligned

- ✅ Rollers were in good condition

- ✅ No visible obstructions

- ✅ Door moved smoothly when operated manually

Yet the problem persisted.

The Real Culprit: Belt Degradation

After ruling out the obvious causes, I decided to take a closer look at the drive mechanism itself. That’s when I discovered the real issue: the belt had degraded significantly.

What I Found

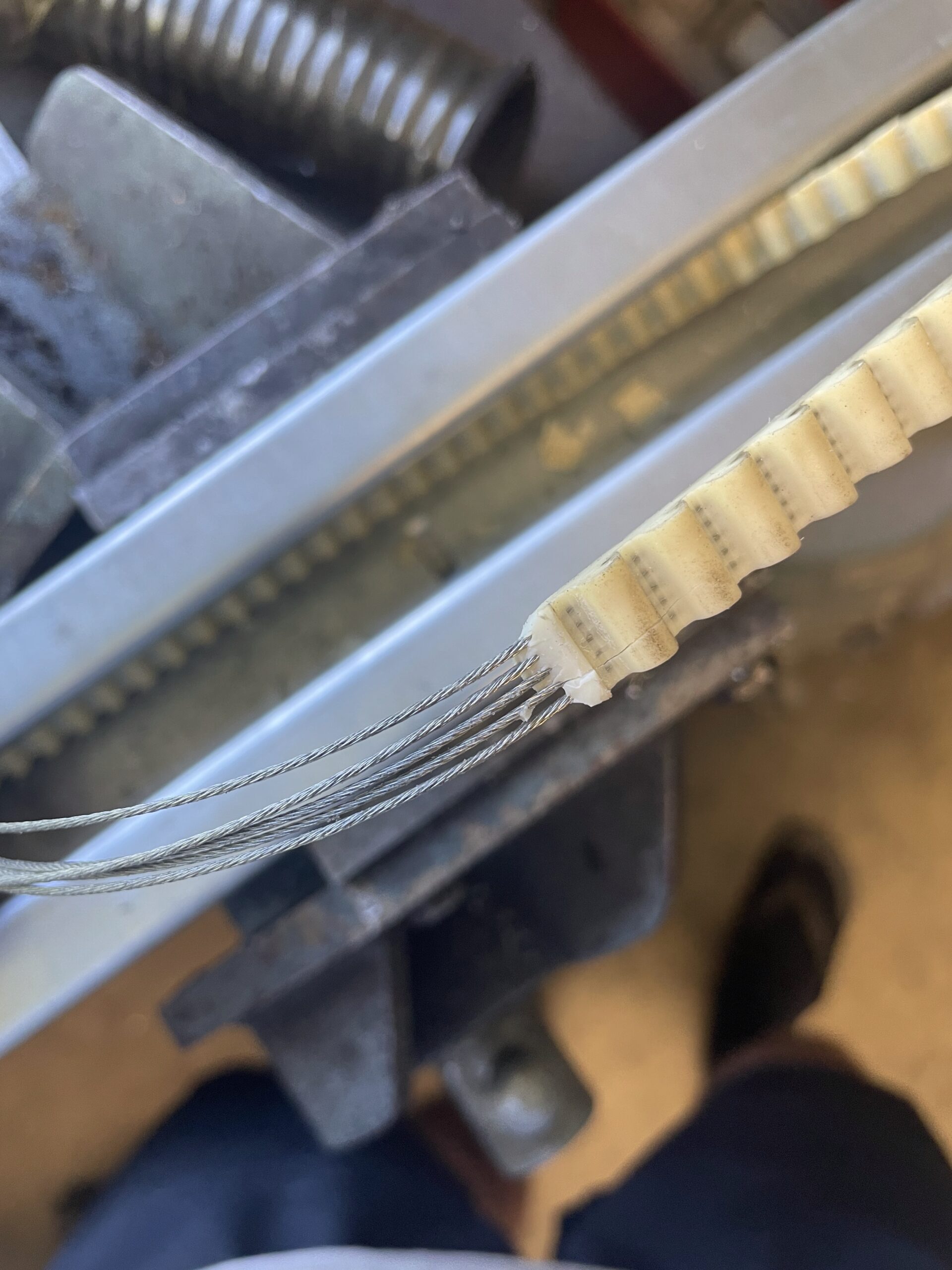

Upon inspection, the belt showed clear signs of wear and degradation (see photos below):

- Material breakdown: The belt material had become brittle and was showing signs of delamination

- Reduced grip: The belt surface that contacts the pulleys had worn smooth, reducing friction

- Stretching: The belt had stretched beyond its optimal tension, causing slippage

- Internal damage: While the exterior might have looked okay at first glance, the internal structure was compromised

Photo showing the degraded belt condition

Close-up view of belt wear and material breakdown

Why This Mimicked Torque Limit Issues

The degraded belt created symptoms that perfectly mimicked a torque limit problem:

- Slippage under load: As the door started to open, the belt would slip on the pulleys, causing the motor to work harder

- Inconsistent performance: The belt’s degraded condition meant it would sometimes grip and sometimes slip, creating unpredictable behavior

- Motor strain: The motor would rev up trying to overcome the belt slippage, making it sound like it was hitting a torque limit

- Incomplete cycles: The belt would slip enough that the door wouldn’t complete its full travel

The Solution

Replacing the belt resolved all the issues. The new belt provided:

- Proper tension and grip

- Consistent performance

- Full door travel without slippage

- Reduced motor strain

Lessons Learned

This troubleshooting experience highlighted an important lesson: symptoms can be misleading. What appeared to be a torque limit issue was actually a mechanical failure in the drive system.

Key Takeaways

- Don’t assume the obvious diagnosis is correct – Even when symptoms point to a common problem, investigate thoroughly

- Check the drive mechanism – Belts, chains, and other drive components can degrade over time and create symptoms that mimic other issues

- Visual inspection isn’t always enough – The belt might have looked okay superficially, but closer inspection revealed the degradation

- Systematic troubleshooting pays off – By methodically ruling out causes, I eventually found the root issue

Prevention

To avoid similar issues in the future:

- Regular maintenance: Inspect belts annually for signs of wear, cracking, or stretching

- Monitor performance: Pay attention to changes in door behavior – they’re often early warning signs

- Replace proactively: Belts have a service life; consider replacement before complete failure

- Keep it clean: Debris and dirt can accelerate belt degradation

Conclusion

What started as an apparent torque limit problem turned out to be belt degradation. This case study demonstrates the importance of thorough troubleshooting and not jumping to conclusions based on symptoms alone. Sometimes the real problem is hiding in plain sight, masquerading as a more common issue.

Have you experienced similar troubleshooting challenges? Share your stories in the comments below!

Leave a Reply